Guide about Types of Home Services

Outline:

– Section 1: Construction and Building Services

– Section 2: Roofing Systems and Maintenance

– Section 3: Sewage Cleaning and Plumbing

– Section 4: Gutter Cleaning and Window Replacement

– Section 5: Moving Services, Solar Choices, and an Actionable Conclusion

Introduction: Your home is a system—structure, envelope, utilities, and the daily logistics that keep everything running. Understanding how services fit together helps you plan upgrades, prevent emergencies, and get more value from every dollar spent.

Construction and Building Services: From Vision to Inspections

Construction and building services turn ideas into walls, wires, and warm rooms. Whether you’re remodeling a kitchen or adding a small office over the garage, success starts long before the first nail is driven. Preconstruction sets scope, budget, and risk controls. A common approach is to keep a contingency of 5–15% for unknowns, since change orders and hidden issues (like outdated wiring or insufficient framing) can add 10–20% to timelines and costs if discovered late.

Two delivery models dominate: general contracting and design-build. A general contractor bids the plans and coordinates trades, while design-build integrates design and construction under one roof to reduce handoffs. For straightforward projects with well-defined drawings, competitive bidding can offer price clarity. For complex or fast-track work, integrated teams often save weeks through earlier problem-solving. Building codes and permits are non-negotiable gates; inspections verify structural integrity, fire safety, and system performance. Expect multiple checkpoints—foundation, framing, electrical rough-in, plumbing pressure tests, and final occupancy.

Quality hinges on materials and sequencing. Moisture control is a recurring theme: air sealing, flashing at windows and doors, and continuous insulation raise comfort and lower utility bills. In colder climates, wall assemblies with higher R-values (for example, R-19 to R-23 in 2×6 walls) and meticulous air barriers can cut heat loss significantly. In hot regions, cool-roof surfaces, attic ventilation, and proper shading reduce cooling loads. Safety standards—fall protection, electrical lockout/tagout, and confined-space protocols—protect crews and occupants.

Consider a realistic schedule. A modest bathroom remodel can run 4–8 weeks; an addition might require 3–6 months depending on site conditions and approvals. To reduce friction, ask for a weekly look-ahead plan that lists tasks, responsible trades, and material deliveries. A good project manager will align dependencies so that, for example, drywall doesn’t arrive before insulation passes inspection. Practical checkpoints to request:

• Preconstruction risk review: utilities, soil, drainage, and code path.

• Cost transparency: labor vs. materials vs. contingency.

• Quality control: mockups for tile layouts, paint samples, and cabinet reveals.

• Closeout basics: manuals, warranties, and a punch list with target completion dates.

For long-term value, specify durable finishes where wear is high (entry floors, kitchen surfaces) and invest in invisible performance—air sealing, balanced ventilation, and right-sized HVAC. These choices typically pay off in lower operating costs and fewer callbacks.

Roofing Systems and Maintenance: Protection Above All

Your roof is the guardian of everything below it. Material choice influences lifespan, energy use, and maintenance. Common options include asphalt shingles (roughly 15–30 years depending on climate and quality), standing-seam metal (around 40–60 years with periodic fastener checks), and tile or slate (50–100 years if the structure supports the weight). Upfront price per square foot varies widely by region, but longer-lived materials can deliver lower lifetime cost when factoring in fewer replacements and reduced storm damage.

Performance comes from the assembly, not just the surface. Underlayment, flashing, and attic ventilation matter as much as shingles or panels. Poor ventilation can trap moisture and heat, accelerating shingle aging and encouraging mold. In snowy climates, inadequate insulation and air leaks create ice dams—meltwater refreezes at the eaves and backs up under roofing. Air sealing at the ceiling plane and sufficient attic insulation (often R-38 or higher in colder zones) sharply reduces the risk.

Maintenance is a small habit that prevents large repairs. After severe weather, a quick inspection can spot lifted shingles, punctures from branches, or missing ridge caps. Flashing is a frequent failure point—look closely at chimneys, skylights, and valley intersections. Warning signs that deserve attention:

• Granules collecting in gutters or at downspout outlets.

• Dark streaks indicating algae or moisture pathways.

• Interior stains on ceilings, especially after wind-driven rain.

• Audible dripping in walls during storms.

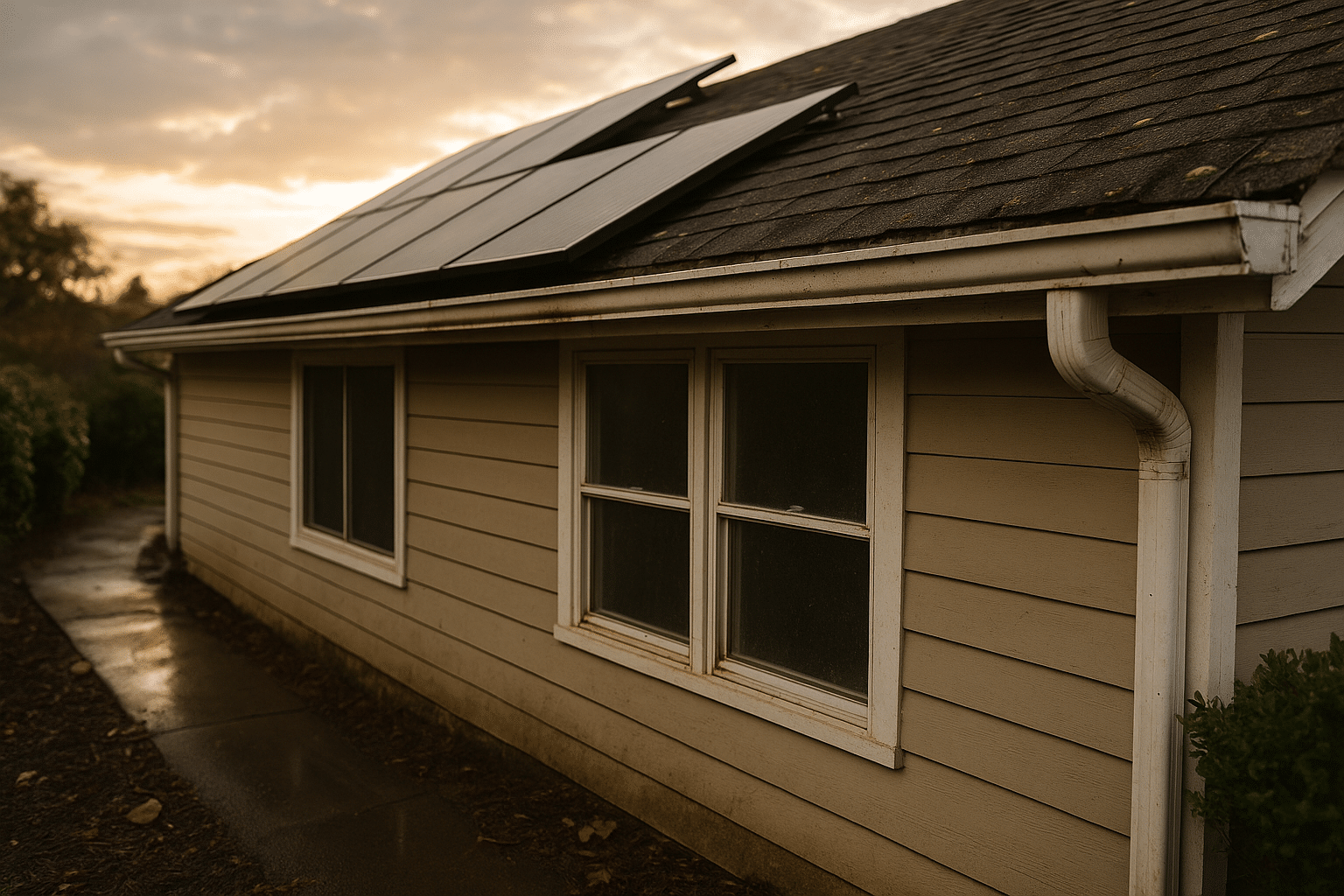

Energy efficiency varies by color and coating. Light, reflective roofs can lower peak attic temperatures in hot regions, easing cooling loads. In temperate areas, insulation and airtightness often have a bigger impact than roof color alone, so address the whole system. If you’re considering adding solar panels later, coordinate roof work now. Mounting on a near-new roof reduces future re-roofing conflicts, and preplanned attachment points help maintain waterproofing. A practical sequence is: evaluate structure, upgrade underlayment and flashing, confirm ventilation, then decide on solar readiness.

Budgeting tips: request a written scope that names tear-off depth, underlayment type, flashing metals, and ventilation targets. Ask for photos of substrate conditions after tear-off and before new materials go down. These artifacts create shared clarity and reduce disputes if issues emerge later.

Sewage Cleaning and Plumbing: Health, Safety, and Flow

Sewage cleaning services and plumbing intersect at a critical point: protecting health while restoring flow. A backup is more than an inconvenience; it’s a sanitation risk. Blackwater exposure can carry pathogens, which is why technicians use personal protective equipment and containment practices. The response workflow typically includes source control, removal of affected materials, disinfection, and verification (often via moisture meters). For safety, areas touched by contaminants may require negative air containment and disposal according to local regulations.

Understanding causes helps with prevention. Common culprits include tree-root intrusion, non-flushable items, grease buildup, and collapsed or offset pipes. In older neighborhoods with clay or cast-iron laterals, tiny separations can admit roots; camera inspections reveal these defects. Hydro-jetting at 3,000–4,000 psi can scour lines, while mechanical augers cut roots—but recurring roots usually signal a structural issue that may require spot repair or pipe lining. Where heavy rain overwhelms combined sewers, backwater valves can mitigate reverse flow into basements.

Plumbers handle the broader system—supply lines, fixtures, venting, and code compliance. Pressure tests confirm that new piping holds under load; dielectric unions prevent galvanic corrosion when joining dissimilar metals. Water quality matters too: hard water scales heaters and fixtures, raising energy use and shortening appliance life. Consider sediment filters or conditioners if tests show high mineral content. Efficiency upgrades, like low-flow fixtures or on-demand recirculation, can reduce water waste without sacrificing comfort.

What to expect from a professional visit:

• Triage within hours for active backups, with clear safety guidance.

• Camera inspection footage provided to the owner whenever feasible.

• A written remediation plan listing clean vs. discard decisions and drying targets.

• Options for permanent fixes (spot repair, lining, or replacement) with pros and cons.

Costs vary by severity and access. A simple clog may be resolved in under an hour; a full-scale cleanup and structural repair can span days. To avoid surprises, ask for a not-to-exceed estimate for the diagnostic phase and request itemized pricing afterward. Prevention beats cleanup: schedule periodic line checks if you’ve had prior incidents, avoid flushing wipes or grease, and install a backwater valve where local codes and site conditions justify it.

Gutter Cleaning and Window Replacement: Water Control and Comfort

Gutters are small components with outsized impact. When they clog, water overflows and attacks fascia, siding, and foundations. Routine cleaning—typically once or twice a year, more often under shedding trees—keeps water moving to the right place. Downspouts should discharge several feet from the foundation, and ground around the home should slope away. During cleaning, check for loose hangers, seam failures, and pinholes. Minor slope adjustments can restore proper flow without full replacement. Guards reduce debris but do not eliminate cleaning; fine mesh handles needles better than wide slots, though extremely fine mesh can slow heavy rainfall.

Quick gutter health checks:

• After a storm, look for washouts beneath downspouts and water stains at eaves.

• During a gentle rain, observe whether water sheets over the edge—often a sign of clogs or improper pitch.

• Inspect for rust, peeling paint, or soft wood behind gutters, which hint at chronic leaks.

Windows influence comfort, energy use, and noise. Replacement paths include insert (keeping frames) and full-frame (new frames and insulation around the opening). Full-frame projects address hidden rot and air leaks but bring more construction. Energy ratings matter: a lower U-factor reduces heat transfer, and an appropriate Solar Heat Gain Coefficient (SHGC) balances winter sun capture against summer overheating. Double-pane, low-emissivity coatings with argon fill are common; triple-pane options can further lower U-factor in cold climates, at the cost of added weight and sometimes thicker frames.

Performance isn’t only about glass. Installation quality governs air sealing and long-term durability. Proper flashing and sill pans direct water out, not in. Expanding foam must be applied thoughtfully to avoid bowing frames. In real-world homes, well-installed, efficient windows can trim heating and cooling use by a noticeable margin, especially when paired with shading, air sealing, and balanced ventilation. A simple plan: replace the worst units first—leaky north-facing windows and any with visible rot—then phase the rest. Consider acoustic-laminated glass near busy streets for comfort beyond energy savings.

Budget and timeline tips:

• Request U-factor and SHGC in writing, suited to your climate zone.

• Ask for cross-sections or samples to verify frame material and thermal breaks.

• Include exterior and interior trim touch-up in the scope to avoid unfinished edges.

Moving Services, Solar Panel Choices, and Your Action Plan

Moving services and solar planning seem unrelated until you map the logistics. Moves introduce deadlines, access constraints, and insurance requirements that ripple through other projects. Service models vary: full-service packing and transport, containerized moves with self-packing, or labor-only loading for rented trucks. Each has different cost structures and risk profiles. Peak season (late spring to early fall) raises rates and reduces flexibility, so early booking matters. Inventory lists, condition photos, and Certificates of Insurance (for buildings that require them) prevent last-minute scrambles. Stair carries, long walks from curb to door, and elevator reservations can add fees—clarify these in the quote.

If you’re relocating and considering upgrades, timing is your ally. Painting, floor refinishing, and deep cleaning are faster in empty rooms. Similarly, roof and electrical work are easier when access is clear. For solar, consider roof age first: installing on a roof with under 10–15 years of expected life can force an early panel removal later. A typical residential system might range from about 4 to 8 kW, sized from historical consumption and roof space. Production depends on location and shading; many areas average 4–6 peak sun hours per day. Payback periods vary widely—rough ranges of 6–12 years are common where utility rates are higher and incentives are available—but the real calculus includes roof condition, financing costs, and future load changes such as electric vehicles or heat pumps.

Quality solar design looks beyond panels. A thoughtful plan evaluates orientation and tilt, wire runs to minimize loss, and inverter strategy (string vs. microinverter architectures). If outages are a concern, pair systems with appropriately sized batteries and essential-load panels, recognizing that storage adds cost and may extend timelines due to additional permits. Speaking of permits, expect electrical and sometimes structural reviews. Clear labeling, accessible disconnects, and conduit routing along clean lines help inspectors and simplify future service. For those moving soon, a pre-listing solar assessment can document system age, output history, and transferable warranties, aiding appraisal discussions.

Conclusion and action plan:

• Start with a holistic checklist: roof health, drainage, windows, plumbing, and electrical capacity.

• Schedule projects in logical order: exterior envelope and roof, then mechanicals, then finishes.

• For moves, lock dates early and confirm building requirements to avoid access conflicts.

• For solar, align installation with roof life and shading realities; document permits and performance.

Home care doesn’t need to be a maze. With a clear sequence and a few data-driven choices, you can lower risk, control costs, and make your space more resilient and comfortable. Keep records, ask for photos at key milestones, and favor durable fixes over quick patches. That steady approach turns a to-do list into a home that works for you day after day.